The main operating locations of our company group are in mainland China, where a welfare committee is established. In addition to complying with the Labor Contract Law of the People’s Republic of China, the Shanghai Municipality Labor Contract Regulations, and local government requirements for labor insurance and health insurance, our company also provides employees with various allowances, bonuses, holidays, cultural and recreational activities, continuing education programs, social insurance, and other related benefits in accordance with relevant Chinese laws, regulations, and policies.

| Category | Specific Project |

|---|---|

| Insurance | Group corporate insurance |

| Compensation | Employee’s salary, performance bonus, dividends, 3 annual festival gifts (money), year-end bonus |

| Benefits | Employee’s birthday gift, marriage, funeral, and maternity allowances, year-end party, pregnancy-friendly work environment, employee purchase discount, travel rewards for outstanding employees |

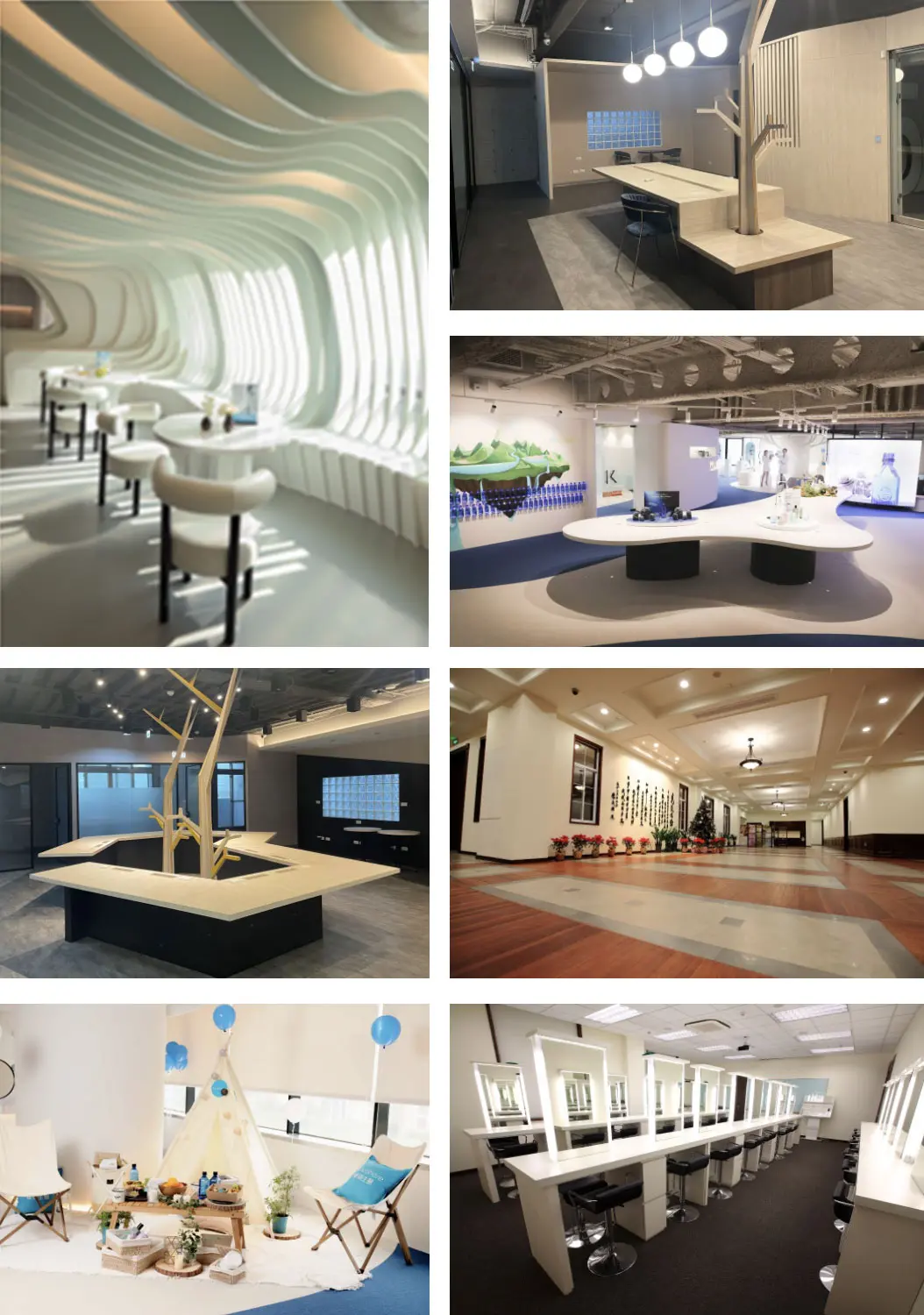

| Health and Happiness | Department employees annual banquet, family activities, charitable activities, and health-related activities |

We establish important annual targets and mandate each subsidiary to perform initial goal-setting for each department (including company goals, departmental goals, and individual goals) at the start of the period. Mid-year progress checks and end-of-year performance reviews are conducted to ensure accurate assessments. The outcomes of these evaluations are used as the basis for promotions, salary adjustments, bonus distributions, and reward allocations, and are also connected to education and training planning. The status of our performance evaluations for 2023 is shown in the tables below:

| Performance Bonus | Awarded based on the company’s operational results and individual work performance. |

| Year-End Bonus | Awarded at the end of the year based on the company’s operational results. |

| Business Bonus | Awarded according to performance or various KPIs. |

| Special Bonus | Awarded for Special Project Contribution. |

| Probationary Salary Adjustment | New employees who perform exceptionally well during their probationary period. |

| Annual Salary Adjustment | Conducted at the beginning of the year, taking into account the company’s operational status for the year, price fluctuations, labor market conditions, and work performance. |

| Special Salary Adjustment | Made in response to talent competition and other special considerations. |

Talent is the most important core competitiveness of the company. Continuous education and training can inspire employees’ personal potential, enhance employees’ knowledge, enable effective use of human resources, and thereby improve the overall operating performance of the company to achieve its business objectives. To enhance the quality and work skills of employees, our company implements pre-job training for new employees upon their arrival. Additionally, management-level employees receive management and professional training based on their needs.

Our company encourages employees to participate in various training programs offered by internal and external institutions to provide them with the latest industry and market information. We actively promote the diverse development of our employees and help them enhance their professional skills. For new employees, we conduct comprehensive training that covers knowledge, skills, and attitudes, including but not limited to the company’s operating philosophy, brand culture introduction, business unit and organizational structure explanation, product and business model introduction, behavioral guidelines and regulations explanation, information security, and financial process explanation. The company’s chief corporate governance officer, accounting manager, audit manager, and their deputies attend the legally required annual training hours each year. In 2024, 5,151 training sessions were conducted, amounting to 11,757 hours.

The subsidiaries (including branch offices) of our group located in Taiwan comply with the “Labor Retirement Fund Act” and related regulations issued by the local government, and have established a defined contribution retirement plan applicable to local employees. Each month, a contribution of no less than 6% of the salary is made to the employee’s individual account at the Labor Insurance Bureau. The payment of the employee’s retirement fund is based on the amount in the employee’s dedicated retirement account and the accumulated benefits, and can be received either as a monthly retirement pension or a lump-sum retirement payment.

The subsidiaries located in mainland China contribute to the pension insurance scheme as required by the government of the People’s Republic of China, by deducting a certain percentage of the total salary of local employees each month. Each employee’s retirement fund is managed and coordinated by the government, and besides the monthly contributions, our group has no further obligations.

In Hong Kong, subsidiary Hong Kong Chlitina International Limited complies with the Mandatory Provident Fund Schemes Ordinance of Hong Kong Special Administrative Region and implements a mandatory retirement plan for employees hired under the Hong Kong Employment Ordinance. This plan defines a contribution retirement benefit scheme managed by an independent trustee. According to the plan’s provisions, both the employer and the employee are required to contribute 5% of the employee’s relevant income. Apart from the monthly contributions, our group has no further obligations.

In Vietnam, subsidiaries Yongli Trading Co., Ltd. and Vinh Le Co., Ltd. comply with the Social Insurance Law and the Law on Health Insurance of the Socialist Republic of Vietnam which stipulate that employers must contribute 21.5% of the total labor wages (including 17.5% for social insurance, 3% for medical insurance and 1% for unemployment insurance), while employees contribute 10.5% of their total wages. For male employees, retirement pensions will represent 45% of their average wage, equivalent to 20 years of contribution to the retirement scheme, and this percentage will increase by 2 percentage points every year up to a maximum of 75% of their average wage. For female employees, retirement pensions will represent 45% of their average wage, equivalent to 15 years of contribution to the retirement scheme, and the retirement pension will increase by 2 percentage points every year up to a maximum of 75% of their average wage. Apart from the monthly contributions, our group has no further obligations.

Comprehensive health examinations can help in the early detection of diseases. The company organizes regular health checks for employees in special job roles (such as those exposed to high noise levels, dust, or X-rays) with specific examination items. In the Taiwan region, an annual health check is organized for all employees. Overseas factories proactively offer health check plans with comprehensive examination items to help employees understand their health status. In 2024, the company organized health checks for all employees. Through internal promotion and dedicated reminders, the attendance rate for health checks in mainland China reached 86% in 2024, while the attendance rate in Taiwan was 97%.

Following annual health checks, professional medical personnel at each office or factory location provide medical assistance and regular check-up reminders for any significant abnormalities identified in the health examination results, ensuring comprehensive care services. For employees with health anomalies, professional consultations are also offered. Regular doctor consultations are held in the office areas to provide employees with professional consultation channels. The company proactively manages and develops plans for education/training, guidance, prevention/risk monitoring, and medical assistance related to individual health anomalies. All employees’ personal health service records and information are used solely to evaluate whether employees are in a safe workplace environment and are not used for any other purposes. This data is securely managed by the dedicated health management unit and is not disclosed externally.

Employee Health Care Over the Past 3 Years:

| Item | 2022 | 2023 | 2024 | |||

|---|---|---|---|---|---|---|

| Mainland China | Taiwan & SE Asia | Mainland China | Taiwan & SE Asia | Mainland China | Taiwan & SE Asia | |

| Number of employees eligible for health check | 560 | 70 | 552 | 148 | 589 | 58 |

| Number of participants | 463 | 70 | 468 | 148 | 506 | 56 |

| Participation rate (%) | 83 | 100 | 85 | 100 | 86 | 97 |

| Item | 2022 | 2023 | 2024 | |||

|---|---|---|---|---|---|---|

| Mainland China | Taiwan & SE Asia | Mainland China | Taiwan & SE Asia | Mainland China | Taiwan & SE Asia | |

| Number of employees eligible for health check | 560 | 70 | 552 | 148 | 589 | 58 |

| Number of participants | 463 | 70 | 468 | 148 | 506 | 56 |

| Participation rate (%) | 83 | 100 | 85 | 100 | 86 | 97 |

To ensure the safety and health of employees and on-site workers, Weishuo (Shanghai) Daily Product Co., Ltd. has established an “Occupational Safety and Health Policy.” This policy includes regular (at least once a year) inspections and maintenance of fire safety and hygiene equipment, escape doors (and stairs), and conducting fire safety drills. The company also provides annual health check benefits for employees and holds annual labor safety and health education and training to ensure a safe and healthy working environment. Through the participation of all employees and the diligent fulfillment of occupational safety and health management responsibilities by managers at all levels, the company is committed to continuously reduce the risk of occupational hazards. The goal is to provide a high-quality, safe and healthy working environment, aiming for zero accidents and sustainable development, to create the most employee-friendly working environment for the Chlitina Group.

To ensure safe production, from January to December 2024, the company organized safety and environmental protection training sessions for a total of 384 employees (including externally certified training). These sessions included: Volunteer Firefighter Emergency Response and Firefighting Drills, Fire Emergency Evacuation Drills, Accident Case Study Safety Education Training, Hazardous Chemicals Accident Response Training with Chemical Specialists, Forklift Operator Training, Environmental Emergency Response Drills, Fire Safety Officer Training, Fire Safety Manager Training, Special Equipment Operator Training, Fraud Detection Training, Winter and Summer Accident Prevention Training, Special Operations Safety Training, and so on. Through these training sessions, employees’ knowledge, awareness, and skills in prevention and emergency response have been greatly enriched.

In view of the frequent spontaneous combustion incidents involving electric bicycles, the company installed 15 sets of hanging dry powder fire extinguishers in the bicycle shed in April 2024 to ensure that any battery fire can be extinguished automatically at the earliest possible moment, preventing the spread of fire. In addition, emergency supplies nearing expiration are regularly replaced. In April 2024, safety helmets due to expire in May were replaced to ensure the proper use of personal protective equipment.

To ensure that environmental pollution sources (wastewater, exhaust gas, noise) meet emission standards, to protect the safety and health of employees in the workplace, and to guarantee the reliability of lightning protection systems in production and office areas:

| Item | Mainland Area | Taiwan & South East Asia Area |

|---|---|---|

| Number of Employees | 776 | 105 |

| Total Worked Hours | 1,620,288 | 210,000 |

| Main category of work-related injury | 0 | 0 |

| Number of injured employees | 0 | 0 |

| Number of days lost due to disabling injury | 0 | 0 |

| Number of reportable injuries | 0 | 0 |

| Number of work-related fatalities | 0 | 0 |

| Occupational disease incidence rate (%) | 0 | 0 |

| Occupational injury incidence rate (%) | 0 | 0 |

| Lost Workdays Ratio (%) | 0 | 0 |

| Item | Mainland Area | Taiwan & South East Asia Area |

|---|---|---|

| Number of Employees | 776 | 105 |

| Total Worked Hours | 1,620,288 | 210,000 |

| Main category of work-related injury | 0 | 0 |

| Number of injured employees | 0 | 0 |

| Number of days lost due to disabling injury | 0 | 0 |

| Number of reportable injuries | 0 | 0 |

| Number of work-related fatalities | 0 | 0 |

| Occupational disease incidence rate (%) | 0 | 0 |

| Occupational injury incidence rate (%) | 0 | 0 |

| Lost Workdays Ratio (%) | 0 | 0 |